With the popularity of optical fibers, there are more and more derivatives of optical fiber products. Optical fiber fusion splicer is one of them. Optical fiber fusion splicers are often used in the construction and maintenance phase of optical cables.

Ⅰ. What is an optical fiber fusion splicer?

Optical fiber fusion splicer is a precise, durable and convenient optical fiber construction instrument specially designed for the installation, operation and maintenance of optical fiber network. Widely used in the field of optical communication, such as the construction, testing and maintenance of optical cables. In optical communication, the construction and maintenance of optical cables are completed by optical fiber fusion splicers.

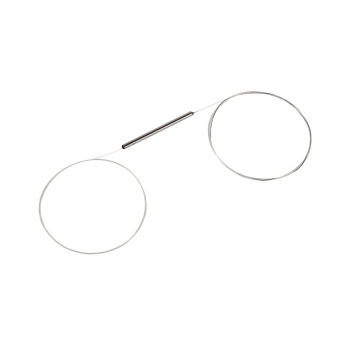

The working principle of the optical fiber fusion splicer is to use a high-voltage arc to melt the cross-section of two optical fibers, and at the same time, use a high-precision motion mechanism to gently push the two optical fibers into one, so as to realize the coupling of the optical fiber mode fields. The alignment of the two fibers is an important factor determining the quality of fiber fusion. The higher the degree of fiber alignment, the better the quality of fiber splicing.

According to the different alignment methods, optical fiber fusion splicers can be divided into two categories: cladding alignment and core alignment. The cladding alignment is the cladding of the fiber rather than the fiber, and the fiber loss after fusion is relatively large. Cladding-aligned fiber fusion splicers are suitable for short-haul transmission in single-mode and multi-mode fiber splicing applications. It is mainly suitable for occasions with low requirements such as fiber to the home, so the price is relatively low; the core alignment fiber fusion splicer is equipped with an accurate core alignment mechanism, 2 specially designed optical lenses and software algorithms, which can accurately identify the fiber type and automatically select the matching welding mode to ensure the welding quality.

Ⅱ. How to use the optical fiber fusion splicer?

1. Strip the fiber optic cable and fix the fiber optic cable on the fiber optic tray.

2. Pass the stripped fiber through the heat shrink tube. Fibers of different bundles and colors should be passed through heat shrink tubing separately.

3. Turn on the power of the fusion splicer and select the fusion splicing method.

4. Prepare the fiber end face.

5. Place the optical fiber.

6. Connect the optical fiber. After pressing the splice button, the fibers move towards each other. When the gap between the fiber end faces is suitable, the fiber fusion splicer stops moving each other, sets the initial gap, measures the fusion splicer, and displays the cutting angle. After the initial gap setting is completed, the core or cladding is aligned, then the fiber fusion splicer narrows the gap (final gap setting), the arc generated by the high voltage discharge fuses the left fiber into the right fiber, and finally the microprocessor calculates the loss and calculates the The value is shown on the display. If the estimated loss value is higher than expected, you can press the discharge button to discharge again, and the splicer will still calculate the loss after discharge.

7. Take out the optical fiber and use a heater to reinforce the optical fiber fusion splicing.

8. Coil the fixed optical fiber. Put the connected optical fiber tray on the optical fiber receiving tray, and fix the optical fiber, receiving tray, junction box, terminal box, etc., and the operation is completed.

EN

EN